Creation Willi Geller Workbook - 2

Part 1

PREPARING

THE METAL FRAMEWORK

The metal framework should be ground

with tungsten carbide cutters or fine - grained ,

ceramic bonded stones .

The framework should be sandblasted with aluminium oxide .

Recommended grit sizes :

Precious metal : 110 mμ

Non - precious metal : 250 mμ

Oxidize the framework according to the manufacturer's instructions

or ...

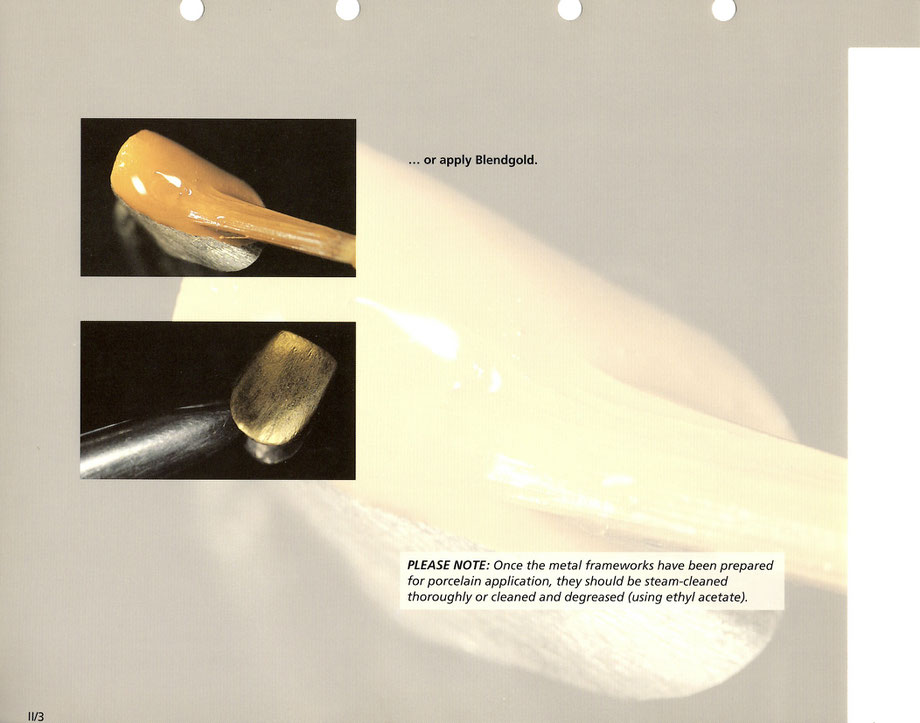

... or apply Blendgold .

PLEASE NOTE : Once the metal frameworks have been prepared for porcelain application , they should be steam - cleaned thoroughly or cleaned and degreased ( using ethyl acetate ) .

APPLYING THE OPACIOUS DENTINE

Seal the surface of the alveolar ridge beneath the pontics

using cyanoacrylate or lacquer and then apply

the separating agent with a" Crea - Pen"

The opacious dentine conceals the thin marginal area of the crown

and prevents excessive shadow effect penetrating the porcelain , including the interdental spaces .Opacious dentine also vitrifies to a slightly higher degree , thus making it more homogeneous and hygienic from the periodontal point of view .This is also very significant as far as the underside of the pontic is concerned and , in addition , stabil izes the shade of the cervical third of the crown .

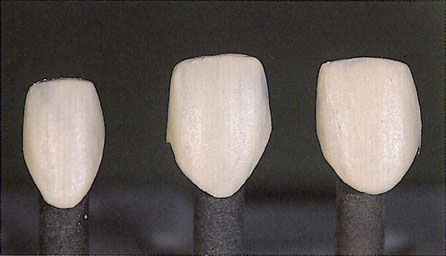

APPLYING THE DENTINE

The labial anatomy of the crown can be built - up with dentine .

Once the anatomical form has been contoured correctly ,

the incisal and interdental areas of the dentine

should be reduced to provide space for the

following layers . Rough , irregularly shaped

areas tend to be advantageous .

Once the anatomical form has been contoured correctly ,

the incisal and interdental areas of the dentine

should be reduced to provide space for the

following layers . Rough , irregularly shaped

areas tend to be advantageous .

Technical tips :

・Once built - up , the porcelain must be kept moist .

Do not allow it to dry too much !

・Should the porcelain have dried out , do NOT moisten it with mixing liquid .

Use distilled water ONLY !

THE FIRST SHOULDER FIRING

The die should be sealed with a very thin coat of cyanoacrylate

or lacquer and separating agent applied around the shoulder with a "Creation".

The framework , which does not fit too tightly ,

should be placed on the die . Opaque shoulder porcelain ( SP - 27 / SP - 28 / SP - 29 depending on the shade selected ) should be applied to the framework / shoulder area to stabilize the brightness value of the cervical region .

The shoulder is then coated with the correct shade

of shoulder porcelain , which is extended to the preparation margin .

Once the porcelain has been dried slightly with a blower

or in front of an open firing chamber ,

the framework can be released easily from the die .

Once the shoulder porcelain has been pre - dried for 2 minutes

at 600 ° C , the first shoulder firing is carried out

at 950 ° C , in vacuum - hold - time : 1 minute .

Shows the shoulder after firing ( egg - shell finish ) .

THE SECOND SHOULDER FIRING

Apply a further coat of separating agent with the ”Crea - Pen” .

The firing shrinkage of the porcelain is compensated for using the correct shade of shoulder porcelain .

After pre - drying for 2 minutes at 600 ° C ,

the second shoulder firing is carried out at 950 ° C , in vacuum - hold - time : 1 minute .

UV view of the fired shoulder .

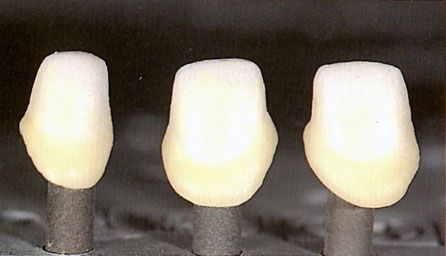

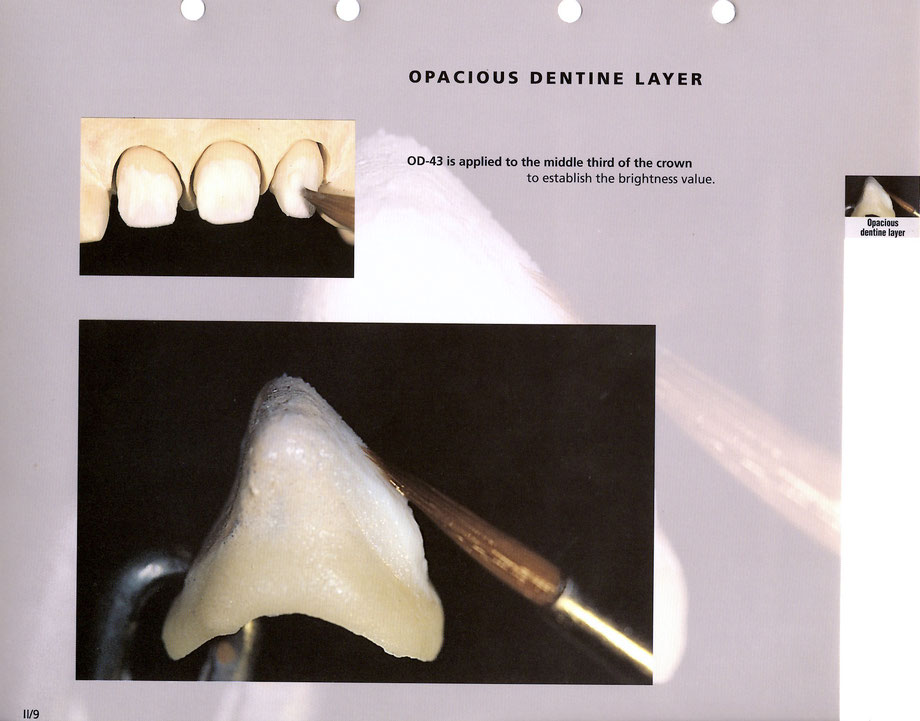

OPACIOUS DENTINE LAYER

OD - 43 is applied to the middle third of the crown

to establish the brightness value .

BUILDING - UP THE DENTINE AND

IRIDESCENT ENAMEL PORCELAINS

The full anatomical form of the crown should first be built - up

with dentine before reducing the labial , incisal , mesial and distal aspects , whereby the mamelons should remain visible in the dentine .

Either the distal or mesial corner of the incisal edge is built - up

first with pure enamel .

The middle incisal area is built - up using enamel ,

opal enamel ( SI 01 - SI 04 ) , opal transparent ,

CL - O or TI porcelains alternately .

THE IRIDESCENT EFFECT

( " MAKE IN " ) PORCELAINS

The iridescent porcelains are soaked into the moist porcelain on the incisal area of the labial surface to reproduce natural mamelons .

The intensity depends on the desired characteristics . MI 61 and MI 63 are usually used .

IRIDESCENT , OPALESCENT

ENAMEL PORCELAINS

The labial surface is completed using enamel , transparent ,

TI - Opal - Transpa and SI - Opal - Enamel porcelains , depending on the effect desired .

The labial surface is built - up excessively to compensate for the firing shrinkage .

Shows TI - 1 porcelain being added to the flanks of the crown

in order to emphasize the bluish / transparent effect .

Using "Crack liners" to simulate a crack in the enamel .

Shows the labial surface after building - up completely .

It can be seen clearly that the labial and incisal contours have been built - up excessively .

PLEASE NOTE : Do not condense the porcelain at any time during building up .