Creation Willi Geller Workbook - 2

Part 2

BUILDING UP THE PALATAL SURFACE

As the palatal surface is still exposed ,

the relationship of the labial surface to the framework can be checked at any time .

The palatal surface is usually built - up with a layer of darker OD

( such as OD - 41 ) or an OD mixture modified with "In Nova" , which decreases in thickness toward the incisal edge .

The area around the tubercle and the bases of the marginal ridges

are built - up with dentine .

WILLI GELLER

In Nova

A mixture of dentine and "In Nova "( Universal modifier ) porcelains

can be used to reproduce dark , discoloured areas in the palatal fossa .

The palatal surface is then completed with enamel ,

transparent and cervical transparent porcelains .

INTERPROXIMAL OPACIOUS DENTINE

A triangular area is removed from the cervical interdental area ,

filled with opacious dentine ( preferably OD - 32 ) and then covered with the desired shade of dentine . This provides for increased light and shade stability .

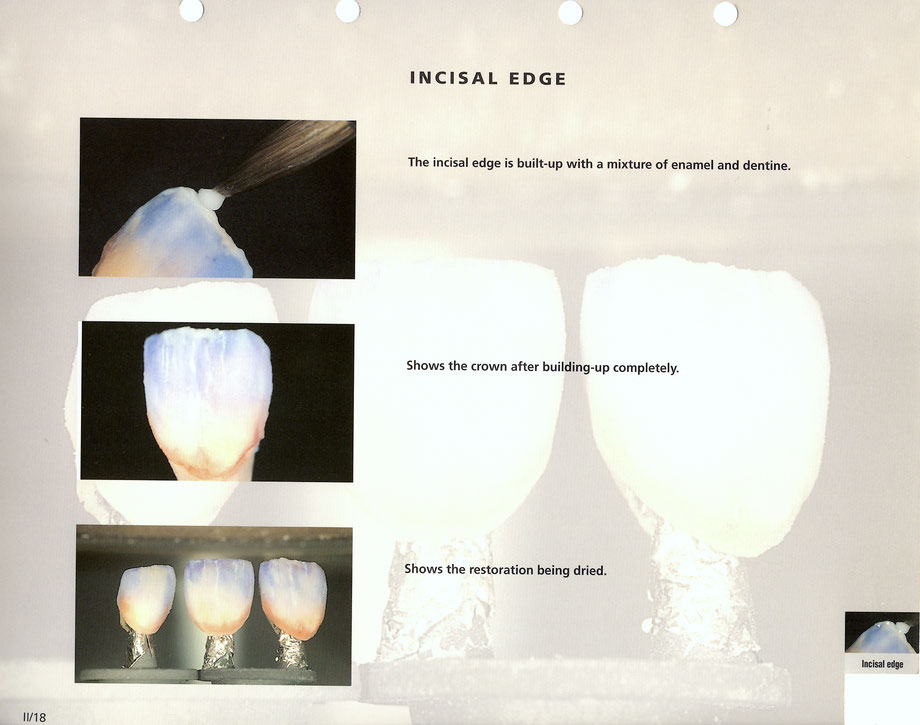

INCISAL EDGE

The incisal edge is built - up with a mixture of enamel and dentine .

Shows the crown after building - up completely .

Shows the restoration being dried .

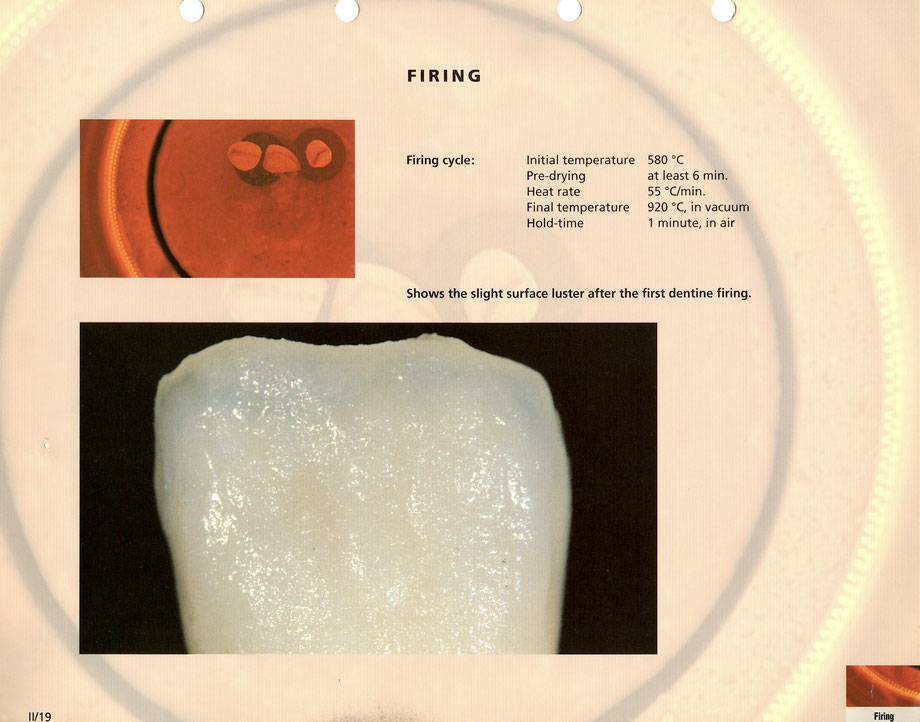

FIRING

Firing cycle :

Initial temperature

Pre - drying

Heat rate

Final temperature

Hold - time

580 ° C

at least 6 min .

55 ° C / min .

920 ° C , in vacuum

1 minute , in air

Shows the slight surface luster after the first dentine firing .

THE SECOND DENTINE FIRING

Assuming that the shade does not require adjusting ,

the contours should be re - built with the following porcelains :

- Shoulder area -

1/3 shoulder porcelain ,

2/3 cervical transparent porcelain ,

- body and incisal areas - CL - O .

The second dentine firing is carried out as follows :

Pre - drying : 4 minutes at 580 ° C , firing : 910 ° C , in vacuum - hold - time : 1 minute .

GLAZING

Discoloured zones on the tooth surface can be reproduced naturally

with " Make - Up " porcelains ( stain and glaze effect ) .

Pre - drying : 2 minutes at 600 ° C .

Glazing is carried out at 930 ° C , IN AIR and with no hold - time .

After glazing in the furnace , the surface of the crown is finished

using mechanical means .

The glaze and surface texture of the restoration can be matched

to the conditions in the mouth using rubber

polishers , sandpaper , felt wheels , pumice and Sidol .

Herausgeber/Publisher: KLEMA Dentalprodukte Ges.m.b.H., A-6812 Meiningen, Austria

Gestaltung/Design: Graphisches Zentrum Hohenems

Ⓒ 1994 by Hämmerle Druck Quintessence, A-6845 Hohenems, Austria